CIG4-8H Introduction

SENSING CIG4-8H GMSL Video Injection Card

The CIG4-8H is a specialized PCIe hardware solution designed to inject pre-recorded or simulated video data directly into automotive Electronic Control Units (ECUs) through authentic GMSL (Gigabit Multimedia Serial Link) interfaces. This enables comprehensive testing and validation of ADAS/AD algorithms without requiring physical cameras or real-world driving scenarios.

Why choose the CIG4-8H video injection card?

The CIG4-8H GMSL Video Injection Card is specifically designed to solve local video injection and simulation validation challenges. Its core value lies in precisely reproducing real-world scenario data flows, accelerating product testing and algorithm iteration through one-time data collection and repeated algorithm validation.

What problems does video injection solve?

Traditional Testing Limitations

Weather Dependency: Testing limited by environmental conditions

High Costs: Vehicle fleet, drivers, insurance, fuel expenses

Safety Risks: Cannot test dangerous scenarios safely

Poor Repeatability: Difficult to reproduce exact conditions

Time Consuming: Weeks/months for data collection cycles

➡️

Video Injection Solution

Controlled Environment: Laboratory-based, weather-independent

Cost Effective: One-time setup, unlimited testing cycles

Safe Testing: Validate dangerous scenarios without risk

Perfect Repeatability: Identical conditions every time

Rapid Iteration: Immediate testing of algorithm changes

Key Customer Pain Points Solved

Development Efficiency Challenges:

- Algorithm Iteration Bottlenecks: Eliminate weeks-long data collection cycles for each algorithm update

- Scenario Coverage Gaps: Access to unlimited edge cases and corner scenarios impossible to collect naturally

- Testing Consistency Issues: Remove environmental variables that affect algorithm validation results

- Resource Allocation Problems: Free up engineering teams from time-consuming field testing logistics

Technical Validation Needs:

- Regression Testing Requirements: Validate algorithm improvements against consistent baseline scenarios

- Multi-Condition Testing: Test across weather, lighting, and traffic conditions without seasonal limitations

- Safety Validation: Validate emergency scenarios (AEB, collision avoidance) without physical risk

- Integration Testing: Coordinate multi-sensor validation in controlled laboratory environment

Three Core Application Scenarios

Real camera data simulation

Virtual scenario testing

Image processing validation

Application Scenario 1: ADAS/AD Algorithm Development & Validation

System Architecture Diagram

recorded data

Real-World Data Injection Pipeline for ADAS/AD Algorithm Validation

Real Camera Data Simulation for ADAS/AD Testing

Multi-condition road marking validation

Pedestrian/vehicle detection accuracy

Multi-weather condition testing

Real-World Data Injection Capabilities:

- Multi-Camera Simulation: Inject real road-collected camera feeds (RAW/YUV formats) through GMSL interface to replace physical camera inputs

- Authentic Scenario Reproduction: Replay actual driving conditions including various lighting, weather, and traffic scenarios

- Algorithm Performance Validation: Test ADAS functions under controlled conditions with real-world data complexity

- Regression Testing: Validate algorithm improvements against consistent baseline scenarios

Application Scenario 2: Simulation Data Algorithm Validation

System Architecture Diagram

Data

Virtual Scenario Data Pipeline for Simulation-Based Algorithm Testing

GPU-Generated Virtual Scenario Testing

User-defined test conditions

Precise hardware injection

Comprehensive validation

Impossible real-world tests

Corner Case Injection Capabilities:

- Pedestrian Crossing Scenarios: Inject sudden pedestrian appearances, jaywalking, and complex crossing patterns

- Object Misidentification Testing: Simulate guardrail misrecognition, shadow confusion, and false positive scenarios

- Traffic Pattern Anomalies: Test unusual vehicle behaviors, construction zones, and emergency vehicle interactions

- Environmental Edge Cases: Validate performance in tunnel transitions, bridge shadows, and complex lighting

Application Scenario 3: ISP Algorithm Simulation Validation

System Architecture Diagram

Data

Raw Image Processing Pipeline for ISP Algorithm Validation

Image Signal Processing Optimization

Sensor-Level Validation

• Raw image data injection

• ISP algorithm verification

• Noise reduction testing

• Color correction validation

System-Level Integration

• ISP output feedback

• Perception algorithm testing

• AEB trigger accuracy

• ADAS system reliability

ISP Algorithm Simulation Validation Capabilities:

- Raw Image Data Injection: Direct injection of unprocessed sensor data for ISP algorithm simulation validation and tuning

- Parameter Optimization: Test noise reduction strength, color restoration accuracy, and exposure control algorithms

- HDR Processing Validation: Evaluate high dynamic range algorithms across various lighting conditions

- Multi-Camera Consistency: Ensure uniform image processing across camera arrays for surround-view systems

System Integration Validation:

- Sensor Fusion Testing: Coordinate ISP output with radar and LiDAR data for comprehensive perception validation

- Real-Time Performance: Validate processing latency and computational efficiency under various load conditions

- Fail-Safe Integration: Test ISP algorithm behavior during sensor degradation or failure scenarios

- Calibration Verification: Ensure proper camera calibration maintenance across different environmental conditions

How to select the right video injection solution?

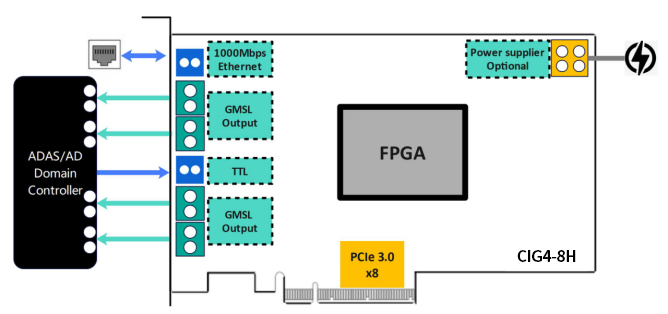

CIG4-8H Hardware Block Diagram and System Architecture

Key Technical Capabilities

The CIG4-8H is designed as a modular system device that can be flexibly configured according to customer requirements. It achieves millisecond-level synchronization accuracy for data replay and meets various specific scenario replay requirements through its rich hardware interface array.

8-Channel Video Output

Support 8×3840×2160@30fps

GMSL video data replay with high precision

Data Synchronization

High-precision synchronization

System accuracy within 1ms

Sensor Fault Simulation

Fault injection testing

Comprehensive safety testing coverage

Camera Functional Safety Simulation Injection

Camera functional safety simulation

Comprehensive validation testing

CIG4-8H Core Specifications

Hardware Architecture Overview

Professional-Grade Hardware Components

ZU7EV MPSoC processor

4,800 MB/s bandwidth

High-speed storage

Component Benefits for Your Application:

- Zynq™ UltraScale+™ ZU7EV: Provides the processing power needed for real-time video injection with hardware acceleration

- PCIe Gen3 x8 Interface: Ensures sufficient bandwidth for 8 channels of high-resolution video data transfer

- DDR4 Memory: Enables smooth buffering and processing of large video datasets

- Trigger Interface: Receives trigger input signals from domain controllers for synchronized operation

Video Processing Capabilities

Core Video Processing Specifications:

- Channel Count: Up to 8 simultaneous GMSL video outputs per card

- Maximum Resolution: 8MP (3840×2160) per channel at 30fps

- Validated Resolutions: eg.1920×1080, 1920×1536, 2880×1860, 3840×2160

- Data Bandwidth: 6 Gbps per channel capacity with full utilization

Comprehensive Video Format Support

YUV422 (8-bit)

RAW10/12/14 (10-14 bit)

YUV422, RAW10/12/14

H.264/H.265 (with GPU decode)

Original (uncompressed)

Format Processing Details:

- YUV422 8-bit: Standard automotive camera format with full color information

- RAW10/12/14: Unprocessed sensor data for ISP algorithm simulation validation

- H.264/H.265 Support: GPU-accelerated decoding for compressed data storage and transmission

- Format Conversion: Real-time conversion between formats during injection process

SerDes Compatibility

Serializer Support

Default: MAX9295A (3G/6G mode switching)

Compatible: MAX96717F, MAX96717

Custom Options: Available on request

Deserializer Support

Validated: MAX9296A, MAX96712

Extended: MAX96716, MAX96718, MAX96722

Adaptable: Custom deserializer support

Additional Features:

- POC Power Supply: Backend domain controller power-over-coax capability for authentic camera connection simulation

- I2C Communication: Complete sensor-ECU interaction simulation including register read/write operations

- Protocol Compliance: Full GMSL2 protocol implementation with proper handshaking and error handling

- Signal Integrity: Maintains authentic electrical characteristics and timing specifications

Multi-Card Scalability & Advanced Features

Scalable Architecture for Enterprise Testing

Multi-card support

Single workstation

Inter-card precision

Parallel testing

Multi-Card Configuration Capabilities:

- Dual-Card Setup: Support for 2 CIG4-8H cards in single industrial PC for 16-channel operation

- Extended Configurations: Up to 4+ cards for specialized high-channel-count applications

- Hardware Synchronization: Sub-microsecond synchronization between multiple cards

- Load Distribution: Intelligent channel allocation across available hardware resources

System Requirements and Integration

Host System Requirements

- Operating System: Ubuntu 18.04/20.04 LTS (other versions adaptable)

- PCIe Slot: PCIe Gen3 x8 or higher

- Memory: Minimum 16GB RAM (32GB recommended for multi-channel operation)

- Storage: High-speed SSD for video data buffering

- GPU: NVIDIA GPU recommended for H.264/H.265 decoding acceleration

Physical Specifications

- Form Factor: Standard PCIe card format

- Weight: 300g

- Power Consumption: 12V @ 1A typical

- Operating Temperature: -20°C to +70°C

- Storage Temperature: -40°C to +80°C

- Humidity: 5%-90% non-condensing (operating), 0%-95% (storage)

- MTBF: 5 years

Cable and Connectivity

- Coaxial Cable: Amphenol Min-fakra Dual MFK2252AW-001-TL30G-50

- Cable Length: Standard 250mm, custom lengths available

- Connector Type: Fakra automotive-grade connectors

- Signal Integrity: Maintains GMSL2 signal quality over extended distances

Software & Driver Support

Software Development Kit (SDK) and Secondary Development Support

Comprehensive Development Ecosystem

C/C++ Interface

Optimized Performance

System Setup

Complete Reference